InnEA's technological innovations

This document aims to summarize the InnEA's technological innovations in the field of biogas/bio-methane production and underline main differences versus the standard technology of the competitors in the Italian market.

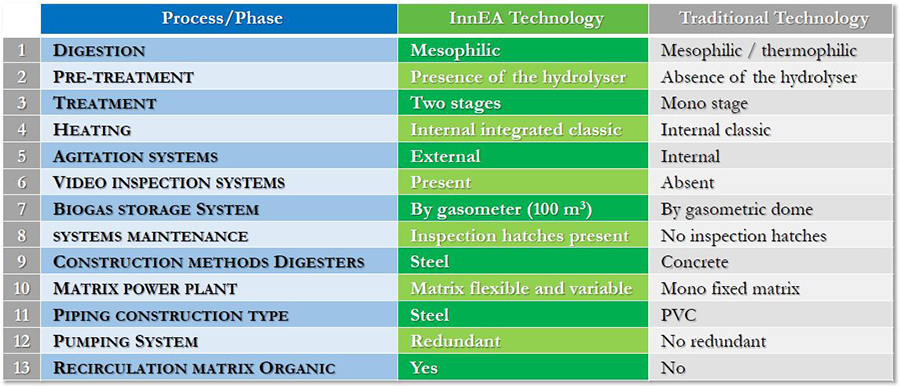

The 13 differentiating features are described below:

- Digestion: The advantage of operating in mesophilic stage compared to the thermophilic stage consists in managing a simplified digestion process and reducing the disintegration time of organic substance;

- Pre-treatment: There are multiple benefits of having a hydrolyser stage of the digestive process:

- Greater efficiency in the use of organic materials, especially in the presence of components of cellulose;

- Through a lower PH there is an abatement of the bacteriological component which improves the digestive process;

- Keep storage of the raw material already predigested that can enter directly in the digestive process by improving considerably the response times;

- Treatment: The dual stage system allows a better bio digestion by increasing by at least a 15% the biogas production;

- Heating: The heating system is of a conventional type, but equipped with control systems related to the parameters measured in the pre-treatment and treatment stages;

- Agitation Systems: Systems of external agitation can be maintained without stopping the digestive process and the integration within the control system is designed to increase the production flexibility of the plant;

- Systems of video inspection: In addition to a chemical and physical control of the digestion parameters through electronic probes, within the stages of treatment and pre-treatment, there are cameras that allow a visual control of the digestive process;

- Biogas storage: Use of the gasometer (much less amount of gas storage than a dome) has the dual advantage of increasing the responsiveness time of the system and to simplify the administrative procedures for the management of the gas storage;

- Maintenance systems: The presence of inspection doors improves the system maintenance;

- Construction methods digesters: There are many advantages of having the blocks made of steel instead of concrete:

- Life span;

- Sealing and reliability;

- Building material recycling (steel can be recycled at premium instead of the concrete cost of disposal);

- Matrix power plant: A flexible and variable matrix allow the recipe to be adapted to the biological variation of the environment;

- Type construction piping: The advantage of having a stronger mechanical resistance and a longer duration;

- Pumping system: A pumping system redundancy can reduce production stops and allow a better maintenance program;

- Recirculation organic: The advantage of having a recirculation system between the primary and secondary digester allows to vary the speed of the fermentation process and to fully exploit the organic matter fed.